October 14, 2020

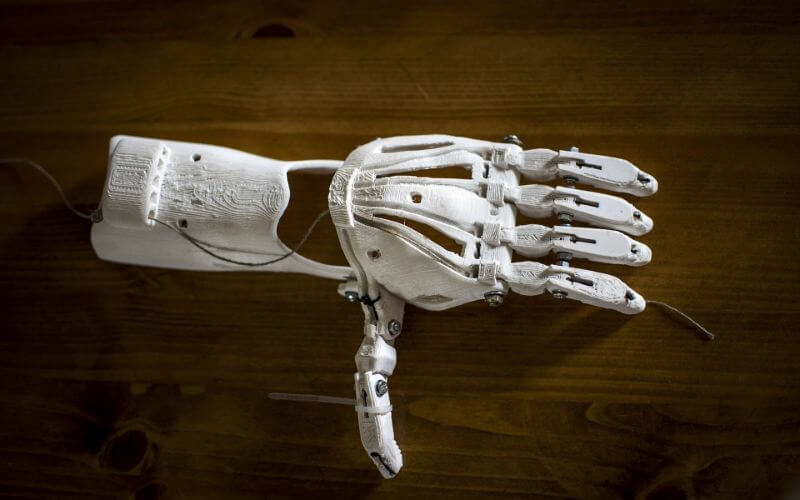

5 things to consider before 3D printing

Often one of the hardest things when it comes to 3D printing (also known as Additive Manufacturing) is understanding the new approach to design that needs to be taken.

Often one of the hardest things when it comes to 3D printing (also known as Additive Manufacturing) is understanding the new approach to design that needs to be taken. Although 3D printing is increasingly being utilised as a quick and efficient method for product prototyping, it requires a whole new way of thinking, and designing, than traditional manufacturing processes (many businesses even develop two designs in parallel – one for 3D printing the initial prototypes, and one for mass manufacturing later down the line).

This is something that I’ve spent much of my career working with SME’s on – developing solutions to bring products to life using 3D printing technologies. But recently I was faced with a slightly different request, brought to me by colleagues at STFC’s UK Astronomy Technology Centre (UKATC) working on the EU H2020 OPTICON project. The team had developed a benchmark design to help understand more about the considerations for 3D printing astronomical components – what features can you create? How can you add additional strength? What is and isn’t possible?

It’s a fascinating project, which will ultimately help the team to optimise the design and reduce the weight of a telescope component, but it also highlighted to me the importance of really understanding the differing design principles of 3D printing to maximise the benefits of the technology. So, thanks to the team at UKATC, I’ve collated this into my top five considerations for optimising your 3D printing.

1. Material matters – There’s a wide range of materials that it is possible to 3D print with, from Polylactic Acid (PLA) used in a range of desktop 3D printers, and providing an inexpensive and easy-to-use material for basic product prototyping, to metal, or carbon fibre filaments. This diversity of materials provides the ability to manipulate the properties of the design, conferring low-weight and high strength, flexibility, thermostability, transparency or chemical resistance, depending on what you’re trying to achieve. Think about the properties you need your product to have as one of your first considerations, this will help you identify a suitable material and 3D printing process.

2. Freestanding features – It’s vitally important to consider any structures in your design that are freestanding. Things like cylinders, clips, walls and unsupported overhangs need support when 3D printing, otherwise you may be looking at collapse on your hands (and a significant amount of wasted time and effort). This can be solved in most cases by integrating additional features such as a radius or a fillet, into the design from the outset. Alternatively you can use a support structure generated in the 3D printing software, which will ensure the design is reinforced while printing, but make sure you consider how this will be removed after the print so that it is not part of the final product (there are a range of techniques to achieve this depending on the printing material used). Considering which features in your design are potentially problematic is essential to ensure you can effectively translate your ideas into the 3D printed world without disappointment.

3. Thick or thin – In traditional manufacturing processes thin materials can be reinforced by adding a range of fixings to mitigate potential weaknesses. However, as 3D printed designs are built in one continuous process with no added fixtures, thin walls and sections are vulnerable to collapse. When developing your 3D print design it’s important to think about how thick the walls of your features need to be. If they don’t reach the threshold, the robustness will almost certainly be compromised.

4. Holes & slots – If your design incorporates holes and slots, this is another big consideration. These features create weaknesses in the print and can collapse if not designed correctly (there’s a theme here!). Generally on our Mlab metal 3D printer if the hole or slot is small (approximately less than 5mm diameter) this can be printed with no support material. If it’s bigger, then there’s a range of options – incorporate support material in the design, change a circular hole to a more stable teardrop shape, or drill the hole in afterwards. It’s important to remember that while 3D printing is an effective solution for many things, sometimes traditional solutions can still be the most pragmatic.

5. Asking the expert – If you’re new to 3D printing, getting expert advice is often the differentiator between success and failure. There are a wide range of 3D printing bureaus across the UK that specialise in supporting the adoption of 3D printing – and of course you could always chat to me…!

To find out more about how STFC can support with 3D printing and prototyping, get in touch or take a look at the website.

Blog post published by Andrew Conley